İnşaattan sorumluyuz----- üretimden sorumluyuz----- eğitimden sorumluyuz

As a dedicated CNC press brake manufacturer, STON designs and builds sheet metal bending machines for cabinet factories, metal furniture plants, door producers and general fabrication workshops around the world.Instead of buying from traders, working directly with a real CNC press brake manufacturer in China gives you better control over quality, delivery and customization. STON integrates R&D, machining, assembly and testing in our own factory, making sure each CNC press brake meets industrial bending requirements. Our machines combine a rigid frame, accurate backgauge and user-friendly CNC control to provide stable bending angles and consistent flange dimensions. Whether you are a distributor, an OEM brand owner or an end-user factory, we help you choose the right model and tooling to match your sheet metal thickness, length and production volume.

| Hayır. | İsim | 63/1500 | 63/2100 | 63/2550 | 100/3200 | 100/4100 | 150/3200 | 150/4100 | 220/3200 | 220/4100 | 250/3200 | 250/4100 | 320/3200 | 320/4100 | Birim | |

| 1 | Nominal basınç | 630 | 630 | 630 | 1000 | 1000 | 1500 | 1500 | 2200 | 2200 | 2500 | 2500 | 3200 | 3200 | KN | |

| 2 | Bükme uzunluğu | 1500 | 2100 | 2550 | 3200 | 4100 | 3200 | 4100 | 3200 | 4100 | 3200 | 4100 | 3200 | 4100 | MM | |

| 3 | Kolon aralığı | 1200 | 1600 | 2050 | 2700 | 3600 | 2700 | 3600 | 2700 | 3600 | 2700 | 3600 | 2700 | 3600 | MM | |

| 4 | Silindir stroku | 215 | 215 | 215 | 215 | 215 | 215 | 215 | 215 | 215 | 225 | 225 | 315 | 315 | MM | |

| 5 | Açılış yüksekliği | 580 | 580 | 580 | 580 | 580 | 580 | 580 | 580 | 580 | 580 | 580 | 680 | 680 | MM | |

| 6 | Boğaz Derinliği | 350 | 350 | 350 | 390 | 390 | 405 | 405 | 405 | 405 | 405 | 405 | 405 | 405 | MM | |

| 7 | Kaydırıcı hareket hızı | Hızlı iniş | 185 | 185 | 185 | 220 | 220 | 180 | 180 | 160 | 160 | 150 | 150 | 130 | 130 | MM/S |

| 8 | Çalışma ilerlemesi | 19 | 19 | 19 | 17 | 17 | 14 | 14 | 12 | 12 | 10 | 10 | 9.5 | 9.5 | MM/S | |

| 9 | Dönüş | 180 | 180 | 180 | 210 | 180 | 180 | 170 | 160 | 150 | 150 | 140 | 120 | 110 | MM/S | |

| 10 | X ekseni hareketi | 500 | 500 | 500 | 500 | 500 | 500 | 500 | 500 | 500 | 500 | 500 | 500 | 500 | 500 | |

| 11 | R ekseni hareketi | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | |

| 12 | X ekseni hızı | 400 | 400 | 400 | 400 | 400 | 400 | 400 | 400 | 400 | 400 | 400 | 400 | 400 | 400 | |

| 13 | R ekseni hızı | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | |

| 14 | Ana motor gücü | 8.7 | 8.7 | 8.7 | 10.8 | 10.8 | 13.2 | 13.2 | 16.7 | 16.7 | 16.7 | 16.7 | 22 | 22 | KW | |

| 15 | Hidrolik yağ hacmi | 130 | 180 | 200 | 300 | 400 | 300 | 400 | 300 | 400 | 300 | 400 | 400 | 500 | L | |

| 16 | Boyutlar (L*M*H) | 2000/1620/2470 | 2600/1620/2470 | 3150/1620/2470 | 3720/1720/2550 | 4620/1720/2550 | 3780/1730/2600 | 4680/1730/2600 | 3830/1800/2670 | 4730/1800/2670 | 3830/1800/2670 | 4730/1800/2670 | 3880/2100/3250 | 4760/2100/3250 | MM | |

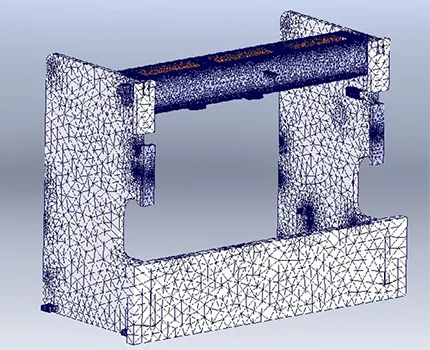

| 17 | Takım tezgahı kalınlığı (dikey plaka, kızak, çalışma masası) | 40/50/60 | 40/50/60 | 40/50/60 | 50/60/80 | 50/70/90 | 60/70/90 | 60/80/100 | 70/80/100 | 70/90/110 | 70/80/100 | 70/90/110 | 80/90/110 | 80/100/120 | MM | |

| 18 | Silindir deliği | 115 | 115 | 115 | 150 | 150 | 180 | 180 | 220 | 220 | 230 | 230 | 270 | 270 | MM | |

| 19 | Silindir çubuk çapı | 110 | 110 | 110 | 145 | 145 | 173 | 173 | 210 | 210 | 220 | 220 | 260 | 260 | MM | |

| 20 | Makine ağırlığı | 4500 | 5000 | 6000 | 8500 | 10500 | 9200 | 11600 | 11000 | 13200 | 11000 | 13200 | 16800 | 19000 | kg | |

| 21 | Yağ pompası akışı | 16 | 16 | 16 | 20 | 20 | 25 | 25 | 32 | 32 | 32 | 32 | 40 | 40 | L | |

As a professional CNC press brake manufacturer, STON focuses on precise bending for carbon steel, stainless steel and aluminum sheets in thin to medium thickness. Accurate control of ram movement and backgauge positions ensures that every bend meets drawing requirements, reducing trial pieces and rework in your workshop.

STON PBS Serisi Elektro-Hidrolik Servo Abkant Pres

STON PBS Serisi Elektro-Hidrolik Servo Abkant Pres

Based on years of experience as a CNC press brake manufacturer, STON designs each machine to help you finish bending jobs faster, with less adjustment and fewer quality issues.

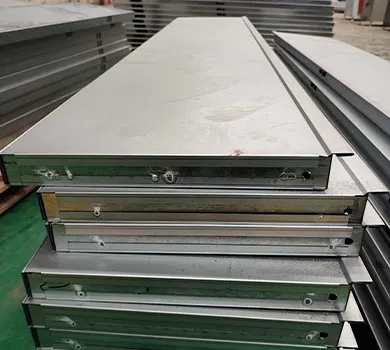

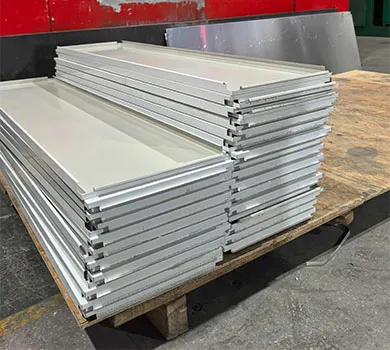

In-house design and assembly of CNC panel benders

Stable supply as your long-term cnc panel bender supplier

Easier customization for special cabinet, door or furniture projects

Servo-driven backgauge axes for precise positioning

Multiple stops to support complex parts with several flanges

Less manual measuring and faster setup between jobs

Graphic programming of bend sequences and angles

Program storage for repeat orders and standard parts

Short learning curve for new operators

Wide selection of punches and dies for different radii and materials

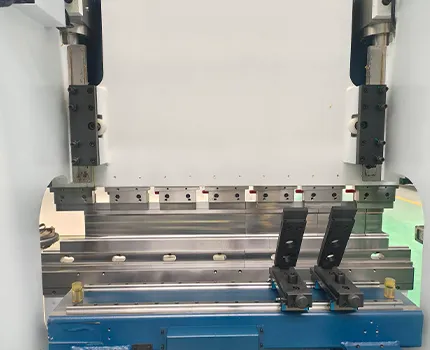

Quick clamping systems to speed up tool change

Custom tooling available for special parts and OEM projects

Crowning and angle correction to compensate deflection

Stable angles from first piece to last in each batch

Reduced scrap rate and fewer customer complaints

Clear access to lubrication and inspection points

Light curtains, side guards and safety interlocks included

Designed to meet industrial safety and maintenance requirements

For electrical cabinets, doors, frames and stainless furniture, bending accuracy directly affects fit, appearance and welding time. By working with a professional CNC press brake manufacturer, you get machines that control ram stroke, pressure and backgauge position with high precision. Proper crowning, quality tooling and stable mechanics help you maintain the same bending angle and flange length across large batches, reducing manual correction and hidden cost in production.

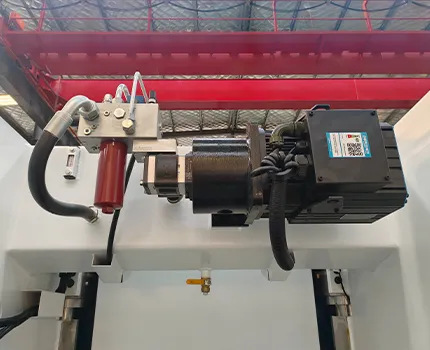

CNC abkant pres makinelerimiz geleneksel hidrolik abkant preslere kıyasla yalnızca 40%-60% enerji tüketir, 75 dB gibi düşük gürültü seviyelerinde çalışır ve bakım maliyetlerini 50%'ye kadar azaltır (hidrolik yağa veya sık filtre değişimine gerek yoktur). 4-8 eksen kontrolü, dijital programlama, akıllı kompanzasyon ve sezgisel insan-makine arayüzü ile küçük partili özelleştirilmiş üretime ve büyük ölçekli verimli işlemeye kolayca uyum sağlarlar. Dahili kendi kendine arıza teşhisi, hızlı sorun giderme ve istikrarlı, uzun süreli çalışma sağlar.

As a CNC press brake manufacturer, we design the frame and ram with high-strength steel, welded and stress-relieved to minimize deformation. Precision guides keep the ram moving smoothly, maintaining parallelism along the entire bending length for consistent angles and straightness.

The servo-driven backgauge system positions sheets accurately for each bend. Multiple fingers and optional axes allow you to handle short flanges, small parts and complex bending sequences, greatly reducing manual trial and error in your workshop.

We supply matched punches and dies together with the machine, based on your typical materials and thicknesses. Quick clamping systems shorten tool changes, enabling fast switching between different jobs and helping distributors or OEM clients build complete solutions around our press brakes.

Depending on the model, the ram is powered by a robust hydraulic system or an energy-saving servo drive. Both options are engineered for smooth speed transitions, stable pressure and low noise, ensuring reliable operation for full-shift production.

The CNC control provides graphic programming, angle calculation and step-by-step bend sequence planning. Operators can easily create, save and modify programs, while diagnostic functions support quick troubleshooting and reduce downtime.

Light curtains, foot pedals with safety interlock, side guards and emergency stops are standard on our CNC press brakes. At the same time, the layout of doors and covers allows easy access to maintenance points, making daily inspection efficient and safe.

Müşterilerimizle güçlü ve şeffaf ilişkiler kurmaya inanıyoruz. Bu nedenle ortaklarımızı son teknoloji üretim tesisimizi ziyaret etmeye ve üretim sürecimizi yakından görmeye davet ediyoruz.

Anthony

AnthonySatın Alma Müdürü, HVAC

Komponent Fabrikası (Almanya)

Jeffrey

JeffreyFabrika Sahibi, Paslanmaz Mutfak Eşyaları

Üretici (ABD)

Jared

Jared- Operasyon Direktörü, Elektrik Kabini

Fabrika (Kanada)

Are you a trading company or a real CNC press brake manufacturer?

We are a real CNC press brake manufacturer in China, not a trading company. We design, assemble and test our press brakes in our own factory, which gives us better control over quality and delivery time.

Please share your material type, thickness range, maximum bending length and typical part drawings. As a manufacturer, we use this information to suggest the correct tonnage, configuration and tooling.

Yes. We can supply standard punches and dies, as well as special tooling if required. This makes it easier for you to start production immediately after installation.

Yes. As a CNC press brake manufacturer, we can customize machine color, logo, nameplates and documents for OEM partners, and adjust configurations to fit your local standards.

For most models, basic installation and training can be completed in a short time, depending on your local conditions. We provide manuals, videos and online guidance, and can arrange on-site service for key projects.

With proper maintenance, our press brakes can serve in industrial environments for many years. We design the frame, hydraulic/servo system and backgauge components to withstand continuous production.

Yes. We keep key spare parts in stock and offer remote technical support. For urgent issues, we can cooperate with your local technicians or arrange our engineers to visit if necessary.

Yes. Besides being a CNC press brake manufacturer, we also produce CNC panel benders, turret punch presses, laser cutting machines and automatic sheet metal production lines, which can be combined into a complete solution for your factory.

Hidrolik abkant pres, bükme kuvveti uygulamak için hidrolik silindirlere dayanır, kalın malzemeler için güçlü tonaj sunar ancak daha fazla bakım gerektirir.

CNC abkant pres ise daha yüksek hassasiyet, enerji verimliliği, daha düşük gürültü ve kolay programlama için servo motorları ve CNC kontrolünü bir araya getirir. CNC abkant presler karmaşık bükme işleri, küçük parti özelleştirme ve yüksek hassasiyetli sac metal üretimi için tercih edilir.

Abkant pres makinesi seçerken şunları göz önünde bulundurun:

Malzeme kalınlığı ve uzunluğu (tonaj ve çalışma tezgahı boyutunu belirler).

Üretim tipi (büyük ölçekli hidrolik abkant pres vs. esnek CNC abkant pres).

Otomasyon ihtiyaçları (CNC sistemi, servo sürücü, arka dayama, bombeleme).

Bütçe ve bakım (CNC abkant presler 30-50% enerji tasarrufu sağlar ve yağ bakımını azaltır).

Bu, sac metal bükme uygulamalarınız için en uygun maliyetli çözümü seçmenizi sağlar.

CNC abkant presler, hassas sac bükme gerektiren endüstrilerde yaygın olarak kullanılmaktadır:

Elektrik dolapları ve muhafazaları

Otomotiv ve havacılık parçaları

Beyaz eşya ve mobilya sacları

İnşaat ve HVAC ekipmanları

Özel imalat atölyeleri

Abkant pres makinesinin uygun şekilde bakımı doğruluk ve dayanıklılık sağlar. Temel uygulamalar şunları içerir:

Hareketli parçaların düzenli yağlanması

Arka dayama ve ızgara cetveli hizalamasının kontrolü

Hidrolik/elektrik sistemlerinin temizlenmesi (hidrolik abkant presler için)

Uygun bükme aletlerinin ve kalıplarının kullanılması

Kendi kendine teşhis ve CNC sistem kontrollerini çalıştırma

Düzenli bakımla CNC ve hidrolik abkant presler istikrarlı, uzun vadeli bükme performansı sağlayabilir.

Commonly, it bends carbon steel, galvanized steel, stainless steel and aluminum sheets within the specified thickness range. Special materials can be evaluated case by case.

Hydraulic press brakes are robust and widely used for general bending. Servo press brakes offer lower energy consumption, higher positioning accuracy and quieter operation, suitable for high-precision or energy-sensitive applications.

Yes. The CNC control can store a large number of bending programs. Operators can quickly recall them when repeating the same parts, saving setup time.

İster mevcut bir hattı geliştiriyor ister yeni bir projeye başlıyor olun, STON üretiminiz için bir CNC çözümünü özelleştirecektir.